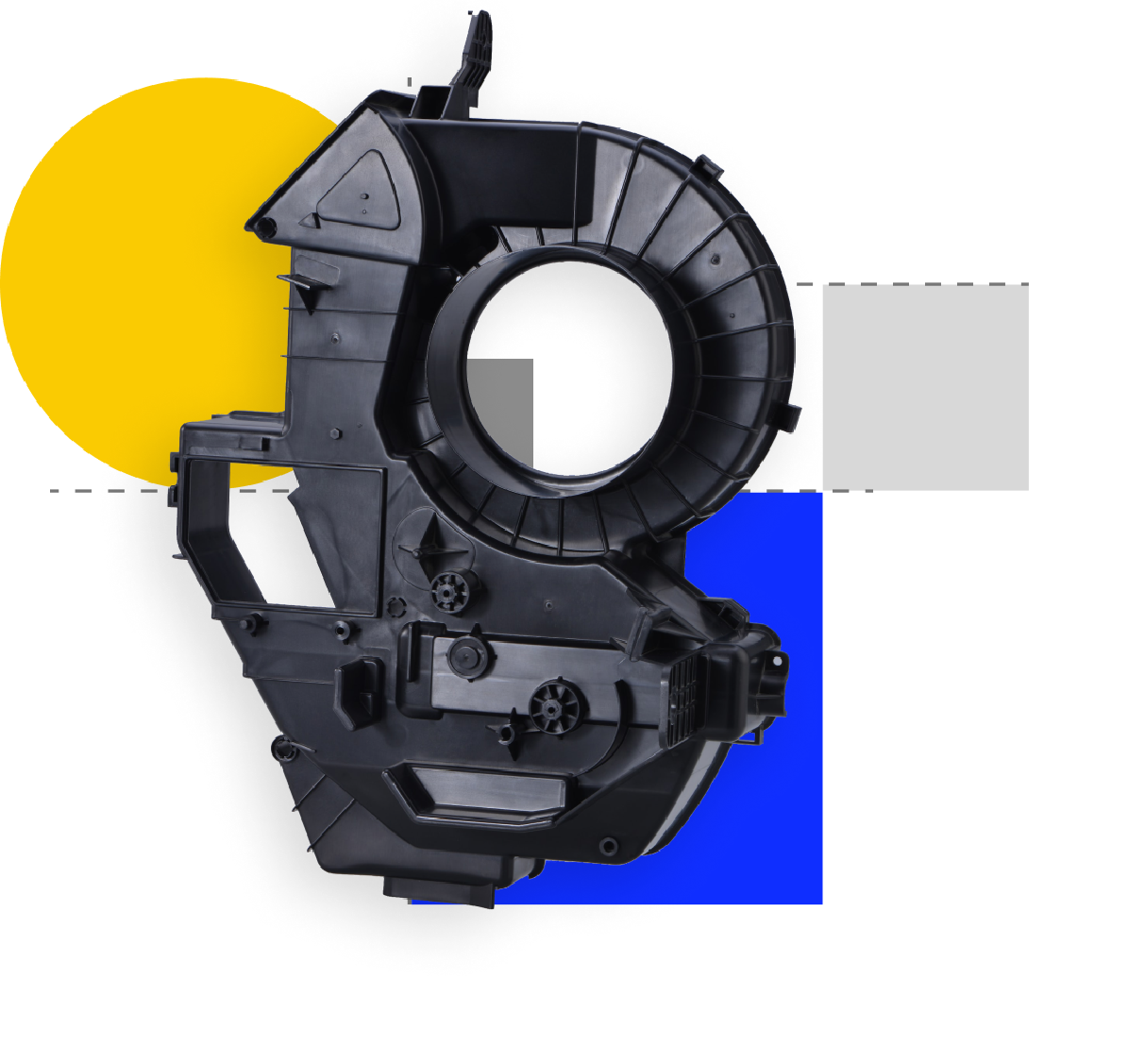

Online Injection Molding Services

Transform your ideas into reality with our high-quality plastic injection molding services. Recommended for +1,000 plastic or silicone parts, our experienced engineers and certified manufacturers ensure the precision and efficiency necessary to bring your designs to life.

Free consultation during your 30 Day Trial

🔒 Uploads are secure & confidential

Why Us

Capabilities

Materials

Advantages

Resources

FAQs

Why sign up to Wikifactory for Business

Simplify the process of finding reliable manufacturing services for your parts exclusively with our Business Plan.

Achieve first-time yield with ease using Wikifactory's hand-picked, quality-assured manufacturers.

Plus, enjoy access to powerful yet user-friendly features that streamline the manufacturing process—only available to Business Plan subscribers.

What our customers say about us

The parts I got were really great. The flexibility offered by Wikifactory’s on-demand manufacturing service is truly remarkable. The platform and manufacturing experts catered to my specific needs. With the prototype working now, I’m happy to move forward and get quotes for new parts.

The Wikifactory service is amongst the best I’ve ever experienced. The transparency and communication throughout the manufacturing process were outstanding. I received regular updates on the production status, ensuring that I was always in the loop. I hope to use the Marketplace for more projects in the future.

The platform offers various manufacturing options, from 3D printing to CNC machining. I could upload my product designs, specify the required materials and quantities, and receive quotations from trusted manufacturers within the Wikifactory network. Great service, with fast response time, and quick turnaround. Our order was perfect.

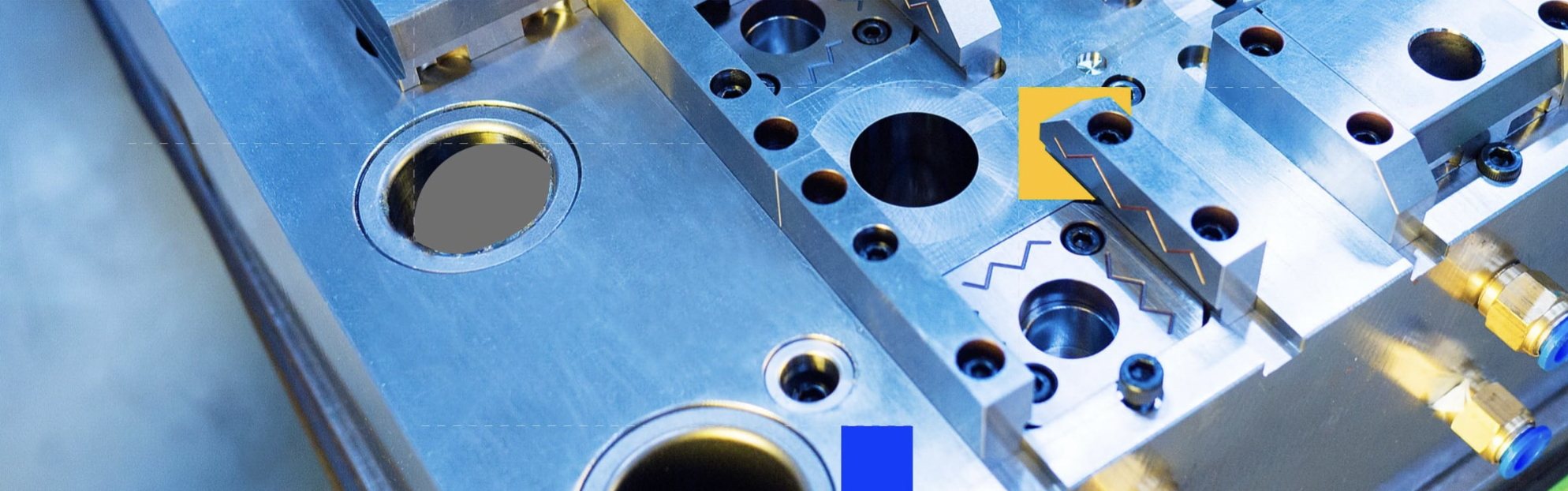

Injection Molding Service Capabilities

Excellent Price

The network of manufacturers ensures a competitive price for your custom parts

Top-Notch Quality

The assurance of high-quality manufacturing standards is guaranteed

Flexible Delivery Options

You have the flexibility to choose from various delivery options that suit your needs

Best Combination of Price, Quality, and Manufacturing Speed

Multiple quotes are evaluated to provide the best balance of price, quality, and speed for your specific part requirements.

Expert Advice and DFM Feedback

You receive expert advice and valuable feedback on Design for Manufacturing (DFM) to help you choose the ideal quote that aligns with your needs.

Cost-Effective Solution

The goal is to assist you in finding the most suitable and cost-effective manufacturing solution for your requirements.

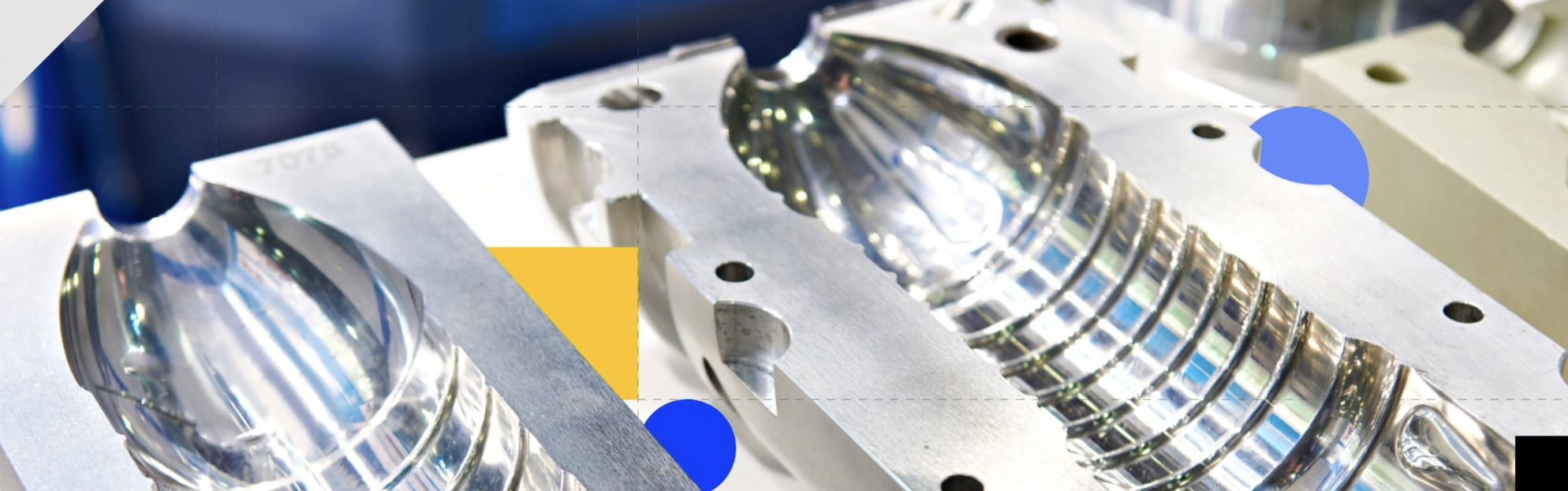

Supported Materials

Types of Plastics

- ABS (Black)

- ABS (Neutral)

- ABS Flame Retardant (Black)

- ABS (White)

- ABS (Clear)

- Nylon 66 (Black)

- Nylon 6 (Neutral)

- Nylon 6 (Black 30% Glass fibre)

- Nylon 6 (Neutral 30% Glass fibre)

- Nylon 66 (Black 25% Glass fibre)

- Nylon (Coloured)

- PEI (Neutral)

- PEI (Black)

- ABS/PC (Black)

- ABS/PC (Neutral)

- Acetal Copolymer (Neutral)

- Acetal Copolymer (Black)

- Acetal Copolymer (Coloured)

- Acetal Homopolymer (Coloured)

- Acrylic PMMA (Clear)

- Acrylic PMMA (Frosted)

- HDPE (Neutral)

- LDPE (Neutral)

- LDPE (Signal White RAL 9003)

- PBT (Black)

- PBT (Neutral)

- PBT (Black, 15% Glass fibre)

- PC (Black)

- PC (Clear)

- PC (White)

- PC (Black 20% Glass fibre)

- PC (Black 40% Glass fibre)

- PC (Coloured)

- PC (Neutral)

- PP (Neutral 20% Glass fibre)

- PP (Random Copolymer, Neutral)

- 6017 S-04

- 8007 S-04

- UHMPWE (Black)

- UHMPWE (Neutral)

- UHMPWE (White)

Types of Liquid Silicone Rubber

- Silicone (Optical Clear - Dow Corning Optical Silicone MS-1)

- Silicone (Transparent - Elastosil LR 3003/30 A&B)

- Silicone (Transparent - Elastosil LR 3003/50 A&B)

- Silicone (Transparent - Elastosil LR 3003/60 A&B)

- Silicone (Transparent - Elastosil LR 3003/70 A&B)

- Other Silicone

Advantages of Injection Molding

Rapid Turnaround

Our manufacturers produce highly accurate parts in as fast as 30 business days.

Efficient Production

Ideal for orders starting with hundreds of plastic or silicone parts.

Precision

Customize your parts to the tolerance options you need.

Customizable Molds

Select from a variety of finishes, tolerances, colors, and materials to customize your injection molded parts.

Fast Manufacturing

Easy to scale to thousands of units at the most competitive price.

Material Selection

Choose from 50+ materials. Please get in touch if the material you require is not listed. We are working to get you innovative and sustainable materials.

Learning Resources

Injection Molding: Top Advantages and Disadvantages

Feel confident that this is the right manufacturing process for you by sharing some of the most discussed injection molding advantages and disadvantages.

Guide to Cost-Effective Mass Production – Injection Moulding

Finding the right manufacturing solution is critical . This guide will help you understand how to use Injection Molding for mass production at the best costs. .